Your professional entry into automated liquid handling

The future-proof system for automation in the laboratory

Every detail is convincing

In the smallest space: pipetting, heating, shaking, cooling

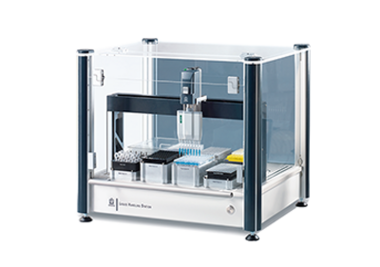

The Liquid Handling Station gives you maximum flexibility for small and medium sample volumes and changing pipetting tasks. The system closes the gap between electronic pipettes and complex, expensive large devices. Your single tubes, 8-tube PCR strips, reservoirs, 96-well or 384-well plates fit on the seven free-loading workstations in ANSI/SLAS format. Three 1-channel liquid ends and three 8-channel liquid ends are available for precise liquid dispensing. With its compact design and space-saving front door, the Liquid Handling Station even fits into confined laboratory spaces.

Discover the comprehensive system for automated pipetting

Heating & Shaking | Cooling | DNA Purification

Overview LHS Application / Technical Notes

Free testing and instruction after personal consultation

BRAND experts will advise you free of charge on the configuration of your instrument and method development. Free tests can also be performed in your laboratory - please contact us.

Andreas Ehlke I Sales north Germany

T +49 160 91890331 I andreas.ehlke@brand.de

Oliver Jenner I Sales south Germany

T +49 160 8836016 I oliver.jenner@brand.de

Benjamin Rienhardt I Switzerland and Austria

T +49 151 70337191 I benjamin.rienhardt@brand.de

United States

BrandTech Scientific Inc.

Tel.: +1 860 767 2562

In USA, call toll-free: 888 522 2726

info@brandtech.com

Benelux

Tel.: +32 470045870

Tel.: +31 625324416

carlos.naipal@brand.de

India

BRAND Scientific Equipment Pvt. Ltd.

Tel: +91 22 42957790

info@brand.co.in

Brazil I Pro-Analyse Quimica

Bulgaria I Aquachim JSLO

Colombia I Scientific Products S.A.S.

Corea I LK Lab Korea Co., Ltd.

France I Prorata

Greece I PNOI Ergastirom S.A.

Hong Kong I Oriental Chemicals & Lab. Supplies Ltd.

Malta I E.J. Busuttil Limited

New Zealand I ScienNze, Ltd.l Lab Supply Ltd.

Peru I Merck Peruana

Slovakia I Labo-SK, s.r.o.

Slovenia I Sanolabor

Spain I LineaLab

Sweden I LBH Advanved Bioservices AB

Switzerland I Spälti-TS AG

Thailand I Bectha i I Phoenix Scientific

Taiwan I Merck WildBlue I Sciteq Co. Ltd.

Liquid Handling Station Custom Labware Order

If your labware is not included in our labware database, you can order a labware file for the required labware (Cat-No. 998160) which can be imported into the software.

- Please send the labware (+ form) to BRAND

- A labware file will be created and then can be imported into the software.

Depending on the labware a custom adapter/rack is required and can be ordered as well (Cat-No. 998134 + 998158).

Frequently asked questions (FAQs)

Yes, the BRAND Liquid Handling Station software has a comprehensive labware database. This can be expanded according to customer requirements if the desired labware is not yet supported by us.

Yes, BRAND offers various passive cooling systems for sample cooling in the Liquid Handling Station. A simple PCR Cooler (709456) and our Cooling Blocks are available for PCR consumables. Microcen-trifuge tubes of different sizes can also be passively cooled with our Cooling Block solutions over a long period of time (up to 3 hours depending on the model). More information at https://shop.brand.de/en/cooling-block-passive-cooler-pp-aluminum-p13786.html

Yes, BRAND offers various passive cooling systems for sample cooling in the Liquid Handling Station. A simple PCR Cooler (709456) and our Cooling Blocks are available for PCR consumables. Microcentrifuge tubes of different sizes can also be passively cooled with our Cooling Block solutions over a long period of time (up to 3 hours depending on the model). More information at https://shop.brand.de/en/cooling-block-passive-cooler-pp-aluminum-p13786.html

BRAND offers passive cooling systems for cooling samples in the Liquid Handling Station. More information at https://shop.brand.de/en/cooling-block-passive-cooler-pp-aluminum-p13786.html.

With the Teleshake 95 module, which is supported by the Liquid Handling Station software, samples in microtiter plates and PCR consumables can be heated and shaken in the robot. More information at https://shop.brand.de/en/shaking-and-heating-module-teleshake-95-for-liquid-handling-station-p9707.html

In principle, the professional operation of safety cabinets is not designed for pipetting robots to be installed in them, as this would significantly change the flow properties in the safety cabinet, among other things.

However, in cooperation with Berner International, a safety cabinet was developed in which our Liquid Handling Station pipetting robot is integrated. This system, marketed by Berner under the name claire® lh, meets the requirements for personal, product and carry-over protection in accordance with DIN EN 12469 - as evidenced by the CE declaration of conformity. As a high-quality system solution comprising a microbiological safety workbench and pipetting robot, the claire® lh enables you to work under GMP-A conditions for the highest quality requirements in your processes. More Information: https://www.brand.de/en/company/newsroom/lhs-integrated-in-berner-claire-lh-safety-cabinet

The liquid ends are changed manually, whereby the change is carried out without force or tools and is displayed by the software via a dialog. The user can be informed of this user intervention via a sound and/or email notification.

To optimize the pipetting results of the liquids you use, we offer numerous adjustment options for pipetting behavior. For example, the user can decide whether the liquid to be pipetted should be dispensed in or outside the liquid of the target well or whether the tip should be wiped off at the edge of the well after the pipetting step. In addition, the Liquid Type Manager integrated in the software has a large number of predefined liquid classes that can be extended and adapted as required. This enables optimum adaptation to specific liquid properties.

Please note that the use of air cushion pipettes is not always advisable for manual pipetting. Air cushion pipettes are recommended for pipetting aqueous solutions of medium density and low to medium viscosity, whereas positive displacement pipettes are preferable for problematic solutions (high viscosity, highly volatile, high density or foaming). As the Liquid Handling Station works according to the air cushion principle, it is possible that a residual film may remain in the tip when pipetting critical media, despite good adjustments in the software.

The Liquid Handling Station can automate a wide range of laboratory tasks, from simple routine tasks to complex pipetting patterns. The Liquid Handling Station shows its strengths particularly in monotonous and therefore error-prone work steps. Once defined, the method runs exactly reproducibly time and time again. Typical applications include PCR and qPCR set-ups, dilution series, replication or reformatting of plates, enzyme assays, general liquid transfers to various labware, sample preparation for a wide range of subsequent analyses and much more. In combination with the SmartExtraction kits, high molecular weight DNA can also be extracted from bacteria, yeasts, tissue samples, whole blood and rodent tails in the Liquid Handling Station.

The Liquid Handling Station software is intuitive to use and allows you to automate pipetting tasks quickly and efficiently without any programming knowledge. The software offers the following functions:

A Basic functions

User-friendly graphical interface that displays the work table of the pipetting robot

Integrated information texts and help for creating complex methods

Four main commands: Transfer (for pipetting tasks), Wait (for waiting times/incubation), Mix (for mixing) and Break (for program interruptions/user interventions)

Device commands for controlling the FlowBox and external devices such as the heating and shaking module

B Extended functions

Professional user management

Predefined liquid properties (liquid types) that can be customized

Expandable disposables database (Labware)

Automatic consistency check to avoid errors

Automatic logging with customizable reports

Context-sensitive help function

Data import/export

E-mail and sound notifications

Progress bar

3D simulation of the programmed methods

Multilingual user interface: German, English, Chinese, Spanish, French

The software enables a simple standard workflow in four steps:

Define name for pipetting task (Method)

Set up the work table

Define transfer commands (Commands)

Start execution (Execute)

The Liquid Handling Station offers several advantages over more complex and expensive large devices, especially for laboratories with medium throughput or specific applications. Here are the main advantages:

A Cost efficiency

Less expensive to purchase and operate than fully automated pipetting robots or large automation platforms.

Lower maintenance costs compared to complex high-throughput systems.

More flexible investment for laboratories with changing requirements.

B Space-saving design

More compact design

Requires less floor space than large liquid handling systems with robotic arms or workstations.

Ideal for smaller laboratories with limited space.

C Simple operation & faster set-up

Intuitive software with user-friendly programming, can be used without in-depth programming knowledge.

Fast commissioning, while large devices often require complex installation and training.

Ideal for non-automated laboratories that want to take their first steps towards automation.

D Flexibility & versatility

Supports different pipetting volumes & vessel types (e.g. tubes, microtiter plates, deep well plates).

Suitable for various applications: PCR setup, ELISA, NGS preparation, dilution series etc.

Quick adaptation to new methods, without programming effort.

E Less maintenance & higher availability

Easy maintenance & cleaning, as there are fewer complex mechanical parts than with large devices.

Less downtime as no complicated robotic components are involved.

Spare parts and calibrations often cheaper and quicker to carry out.

F Lower operating costs

Lower energy consumption compared to large robot systems.