Definition of 'dispensing':

The term 'dispensing' is understood to mean the discharge of defined quantities. For easy, rapid and precise dispensing of reagents, bottle-top dispensers are widely employed to replace poured transfers into graduated cylinders. They can be mounted directly on commercial laboratory bottles, either directly or by means of adapters. It is no longer necessary to transfer or decant chemicals. Serial dispensing in particular is greatly facilitated.

Functional principle of bottle-top dispensers

By an upward movement of the piston, the preset amount of liquid is aspirated from the reagent bottle into the dispenser cylinder. By the subsequent downward movement of the piston, the liquid is released through a valve system and the discharge tube. There is no need to set a meniscus or to observe a waiting time.

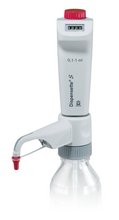

Bottle-top dispensers with floating pistons, e.g., Dispensette® from BRAND

For dispensing aggressive reagents, e.g., concentrated acids such as H3PO4, H2SO4, bases like NaOH, KOH, saline solutions, as well as many organic solvents: Dispensette® S

For dispensing organic solvents, such as chlorinated and fluorinated hydrocarbons (e.g., trichlorotrifluoroethane and dichloromethane), or acids such as concentrated HCl and HNO3, as well as for trifluoroacetic acid (TFA), tetrahydrofuran (THF) and peroxides: Dispensette® S Organic

For dispensing HF we recommend the use of the Dispensette® S Trace Analysis with a platinum-iridium valve spring.

Documents download

Bottle-top dispensers with wiping-seal piston, e.g., seripettor® from BRAND

The design of the system allows a replacement of the complete dispensing cartridge. The somewhat higher operating forces dur-ing filling are minimized by a spring with automatic lifting action. The present example reflects a competitively-priced dispenser for simple dispensing tasks in the volume range of 0.2 to 25 ml.

Range of application and materials

The range of application in-cludes the daily routine dispens-ing of bases, acids in low con-centration, biological buffers, cell culture media, biological detergents and polar solvents.

The seripettor® pro dispenser is suitable for dispensing acids such as concentrated HCl, po-lar solvents (e.g., acetone) and UV-sensitive media. In contrast to the seripettor® dispenser, valves made from chemically resistant materials are used in this instrument.

Documents download

Repetitive pipetting – perform long series quickly and reproducibly

With repetitive pipettes (also known as steppers), a single aspirated volume can be dispensed precisely step by step. This allows long test series to be processed reproducibly and quickly and simplifies complex sequences providing both high efficiency and accuracy. Due to the positive displacement principle used, even handling of problematic liquids is possible.

The positive displacement principle

The positive displacement principle is often used for repetitive pipettes.

In contrast to air cushion systems (e.g., in micropipettes), the piston of positive displacement systems has direct contact with the liquid to be pipetted. When aspirating, the piston draws in the liquid by creating a vacuum and then wipes the walls of the tip clean during dispensing

Advantage

This operating principle ensures precisely reproducible results regardless of the liquid and without the influence of an air cushion. Viscous liquids, highly volatile solutions, or foaming media can be accurately and easily dispensed.

Manual or electronic – the right model for every application

The manual repetitive pipette

e.g., HandyStep® S from BRAND

Routine work, production or long series can be handled efficiently with a manual repetitive pipette. With the simple setting wheel, the most common volumes can be set easily and quickly.

- Robust and durable

- Quickly adjustable volume

- Easy to use and compatible with tips from other manufacturers

The electronic repetitive pipette

e.g. HandyStep® touch and HandyStep® touch S from BRAND

Complex processes and extensive protocols can be efficiently implemented with electronic repetitive pipettes. The electronic volume adjustment ensures high flexibility in volume settings. The touch display and range of functions enable almost any test procedure.

- Simple: Touchscreen operation similar to a smartphone

- Easy: Electronic tip ejection

- Efficient: Recognition of tip size of BRAND PD-Tips II, but also compatible with tips from other manufacturers

The right choice

With so many possibilities, it can be difficult to make the right choice for your applications. Positive displacement or air cushion? Manual or electronic? Simple for standard applications or extended functions for complex processes?

The range of devices is just as diverse as the applications.

Our Application Notes will help you make the right choice and find the perfect device for your application.

Documents download

Safety always comes first!

When choosing a bottle-top dispenser, the safety features of the instrument should be kept in mind. For example, does it reduce the risk of injury due to glass breakage? How does it avoid accidental splashing when the instrument is primed? How is contact with the medium minimized when the dispensing tube is closed? Likewise, the suitability of the dispenser for the medium to be dispensed should be checked by the user. Information about this can generally be found in the operating manual in the chapter 'Function and limitations of use'. When in doubt, contact the manufacturer directly. Information on maintenance and monitoring of measuring instruments are also found in the operating manual.

Monitoring of measuring instruments / calibration

In regard to the monitoring of measuring instruments according to ISO and GLP guidelines, the accuracy of volumetric instruments should be checked regularly and recalibrated if necessary.