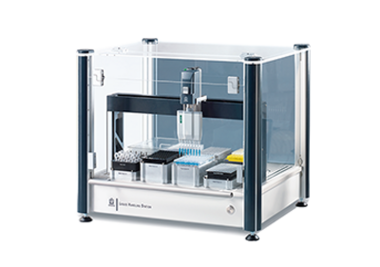

Your professional entry into automated liquid handling

The future-proof system for automation in the laboratory

Every detail is convincing

In the smallest space: pipetting, heating, shaking, cooling

The Liquid Handling Station gives you maximum flexibility for small and medium sample volumes and changing pipetting tasks. The system closes the gap between electronic pipettes and complex, expensive large devices. Your single tubes, 8-tube PCR strips, reservoirs, 96-well or 384-well plates fit on the seven free-loading workstations in ANSI/SLAS format. Three 1-channel liquid ends and three 8-channel liquid ends are available for precise liquid dispensing. With its compact design and space-saving front door, the Liquid Handling Station even fits into confined laboratory spaces.

Discover the comprehensive system for automated pipetting

Heating & Shaking | Cooling | DNA Purification

Overview LHS Application / Technical Notes

Free testing and instruction after personal consultation

BRAND experts will advise you free of charge on the configuration of your instrument and method development. Free tests can also be performed in your laboratory - please contact us.

Andreas Ehlke I Sales north Germany

T +49 160 91890331 I andreas.ehlke@brand.de

Oliver Jenner I Sales south Germany

T +49 160 8836016 I oliver.jenner@brand.de

Benjamin Rienhardt I Switzerland and Austria

T +49 151 70337191 I benjamin.rienhardt@brand.de

United States

BrandTech Scientific Inc.

Tel.: +1 860 767 2562

In USA, call toll-free: 888 522 2726

info@brandtech.com

Benelux

Tel.: +32 470045870

Tel.: +31 625324416

carlos.naipal@brand.de

India

BRAND Scientific Equipment Pvt. Ltd.

Tel: +91 22 42957790

info@brand.co.in

Brazil I Pro-Analyse Quimica

Bulgaria I Aquachim JSLO

Colombia I Scientific Products S.A.S.

Corea I LK Lab Korea Co., Ltd.

France I Prorata

Greece I PNOI Ergastirom S.A.

Hong Kong I Oriental Chemicals & Lab. Supplies Ltd.

Malta I E.J. Busuttil Limited

New Zealand I ScienNze, Ltd.l Lab Supply Ltd.

Peru I Merck Peruana

Slovakia I Labo-SK, s.r.o.

Slovenia I Sanolabor

Spain I LineaLab

Sweden I LBH Advanved Bioservices AB

Switzerland I Spälti-TS AG

Thailand I Bectha i I Phoenix Scientific

Taiwan I Merck WildBlue I Sciteq Co. Ltd.

Liquid Handling Station Custom Labware Order

If your labware is not included in our labware database, you can order a labware file for the required labware (Cat-No. 998160) which can be imported into the software.

- Please send the labware (+ form) to BRAND

- A labware file will be created and then can be imported into the software.

Depending on the labware a custom adapter/rack is required and can be ordered as well (Cat-No. 998134 + 998158).