Smart technology for individual filling tasks

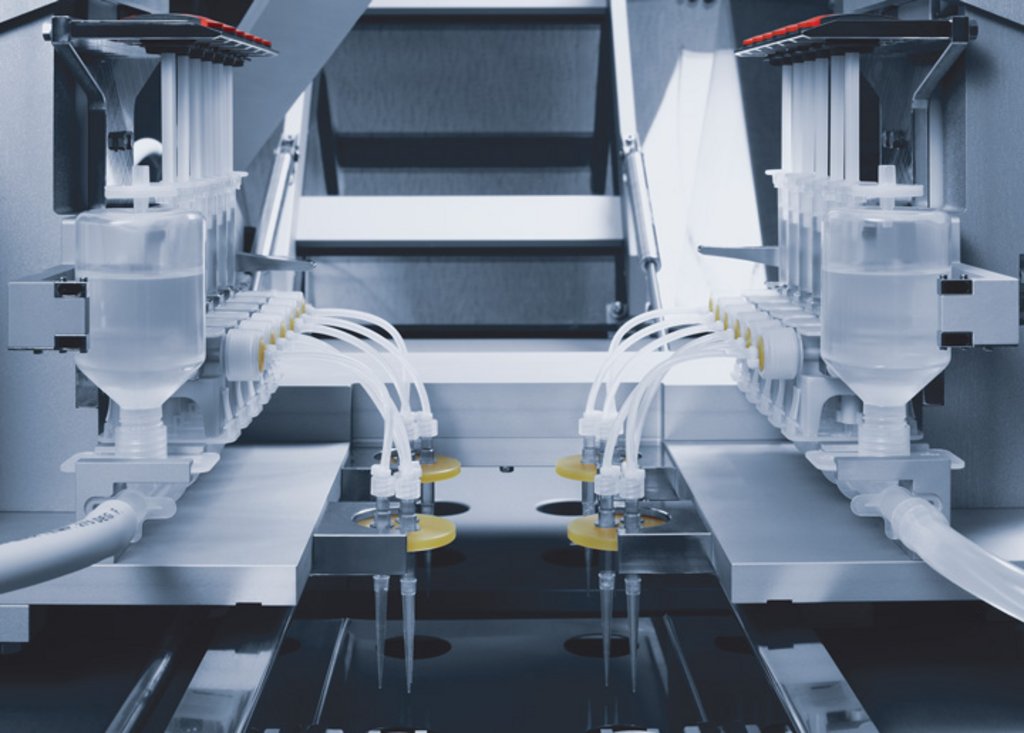

Our innovative and high-precision dosing technology incorporates advanced system components from our world-renowned Liquid Handling instruments. They are combined with highquality, reliable component groups and modules from automation and control technology according to your requirements.

BRAND dosing systems can be integrated into complex filling and packaging lines as needed, and can be customized to individual specifications. Thus, they offer a broad range of possible applications, and are well suited for high-throughput filling lines.

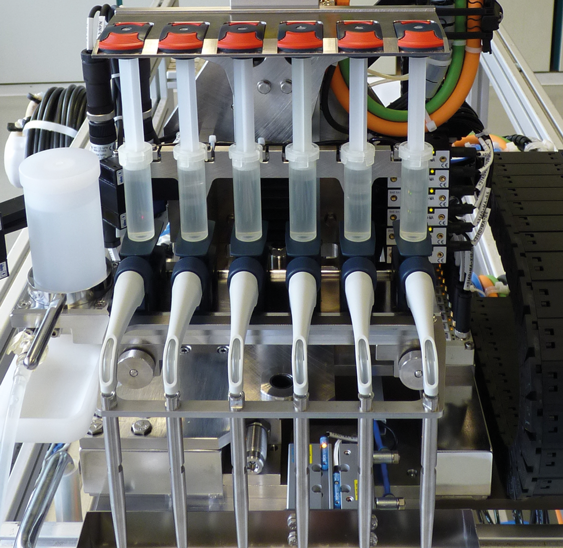

seripettor® dispensing system

High-precision dosing technology based on the seripettor® bottle-top dispenser. The system works with reliable seripettor® components that are specially modified for use in high-performance dosing systems.

Dosing module with autoclavable, stainless steel media Distributor

For routine use in sensitive Areas

Key media-carrying components as valve head with dispensing tube, dispensing cartridge and level control container are made of plastics and can be easily exchanged.

Advantages of the seripettor®

- The dispensing cartridges, membrane filter, and pre-mounted valve heads are disposable and easily replaceable without using tools. They can be supplied sterile if needed

- The media distributor and level control container are easy to disassemble, clean and autoclave

- No calibration of the dosing system is necessary after replacing the disposable items

- The low dead-space design for media-carrying channels means minimal loss of media during cleaning or when changing media

- Design provides low maintenance overhead and minimal downtime

- High precision dosing is combined with long-lasting durability

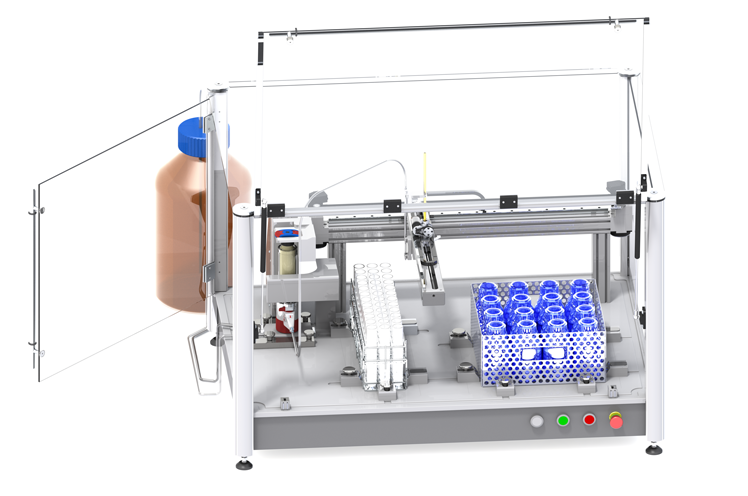

FD (fully disposable) dosing module

For the consumer area

All media-carrying components can be replaced quickly, easily, and cleanly by changing the complete plastics made dosing module in a plug´n play process.

Plug‘n Play

Based on the seripettor® dispensing technology an entirely novel, completely replaceable, single-use dosing module made of exceptionally high quality plastics has been developed. The modular design of the segments allows an individual assembly. The system offers the greatest possible flexibility in the dosing module arrangement. At BRAND, manufacturing and assembly can be conducted under validated cleanroom conditions (ISO 14644-1, Class 8).

Advantages of the FD dosing System

The FD dosing module makes CIP/SIP processes a thing of the past, and eliminates all the associated system technology. This means:

- No additional expenditures for complex cleaning systems

- No more cleaning and sterilization validations necessary

- No residue due to cleaning errors

- No more cleaning required (for huge time savings and productivity gains)

- Minimal downtime in production facilities

- Reduction of process risks

- Cross-contamination is largely eliminated