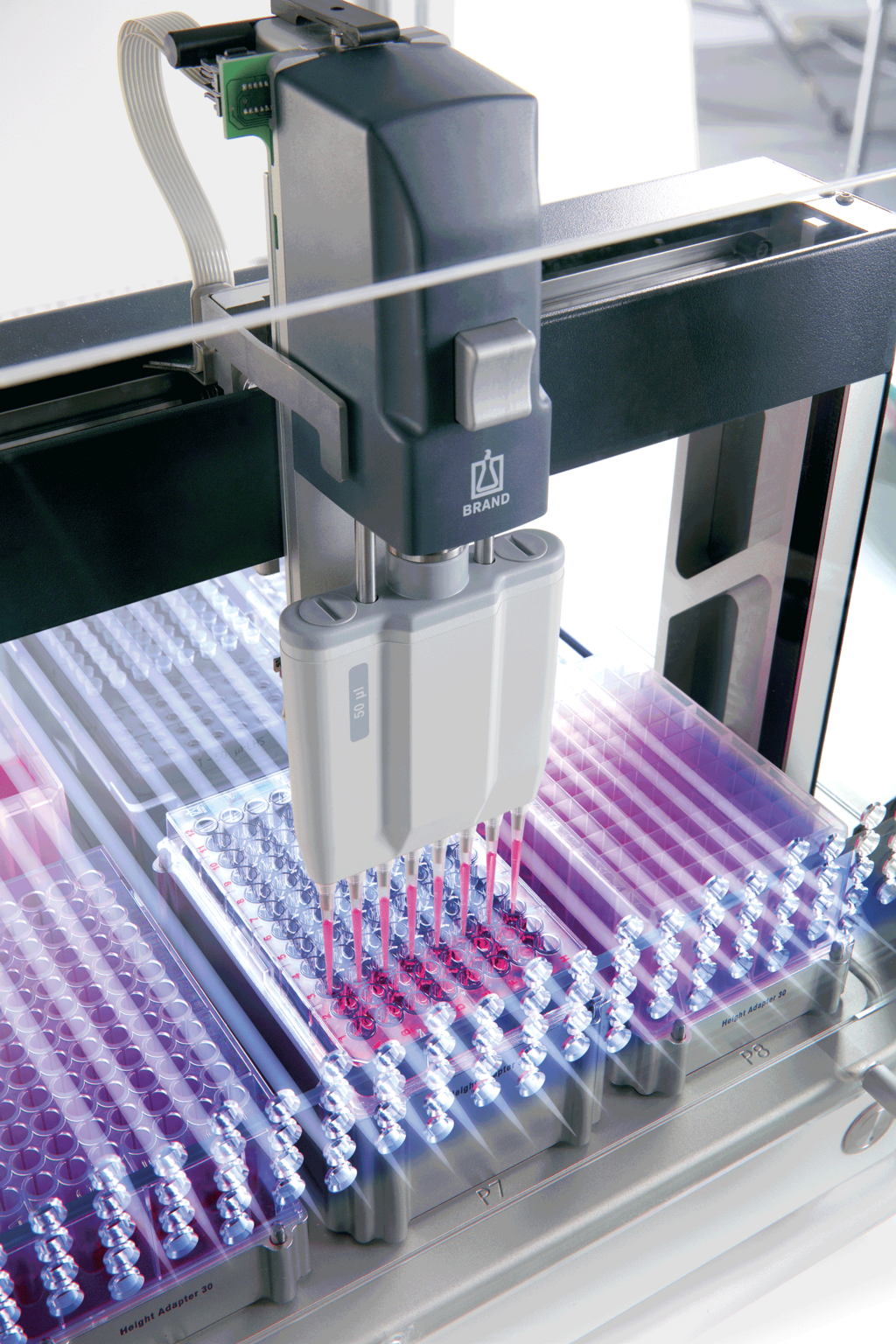

Liquid Handling Station flow

A Small Cleanroom inside your Lab

The newly developed FlowBox of the Liquid Handling Station flow provides cleanroom conditions at your workbench. The HEPA filter (HEPA 14 according to DIN EN 1822) cleans the intake air, then directs it horizontally in a laminar flow across the workplaces inside the Liquid Handling Station. With the door closed, the air inside the cabinet is replaced approx. 260 times per hour (at a volume flow rate of 22 m3/h), and exits through special openings in the front door. The system meets cleanroom requirements of ISO 14 644-1 (Class 5) and GMP Annex 1 (Class A) in the work area and thus protects the samples from airborne contamination.

In addition, the software performs a three-minute air flushing routine before starting the pipetting process, leaving no measurable particles (particle sizes 0.5 μm, 0.7 μm, 1.0 μm, 3 μm, and 5 μm) inside the cabinet. During the pipetting procedure, the air flow is controlled automatically and increases to 29 m3/h when the front door is opened, preventing unfiltered air from entering the workplace of the Liquid Handling Station.

It goes without saying that the Liquid Station flow offers the same benefits as the popular Liquid Handling Station. Both versions of the BRAND pipetting robot save space in the lab and are very easy to operate. With just a few mouse clicks you set up your own, customized method.

BRAND also offers a free Method Check for the Liquid Station flow. As part of this Method Check, BRAND will provide the new Liquid Handling Station flow pipetting system to you for a two-week on-site validation period free of charge.